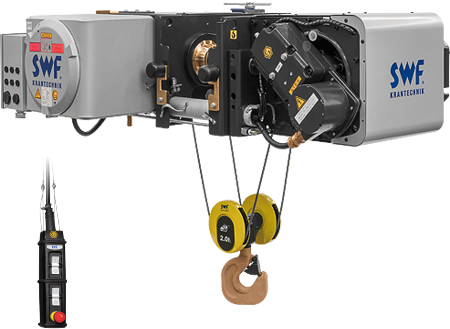

Wire Rope Hoist

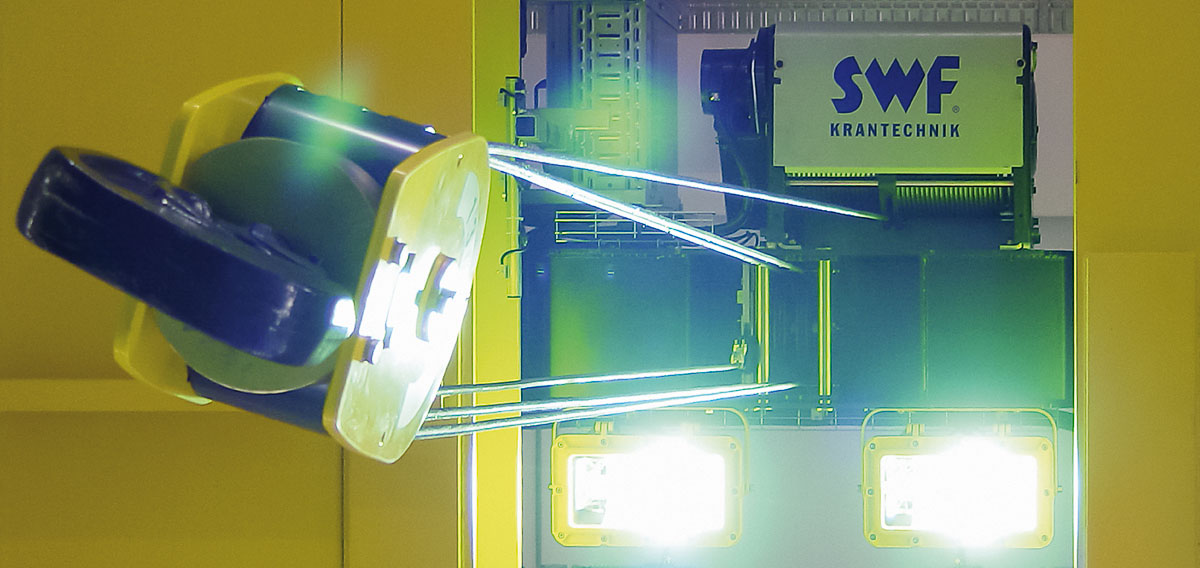

NOVAex

Our NOVAex electric wire rope hoists combine the reinforced NOVA with the special operational requirements needed for working in explosive atmospheres. The focus of the NOVAex is clear: top safety and reliability.

Thanks partially to the capsuled electrical components, the NOVAex is ideal for the potential equalisation of all conducting components and various protective functions, and for handling tasks in explosive atmospheres (gas zones 1 and 2, dust zones 21 and 22). The large diameter of the rope drum, which allows for almost vertical lifting and optimal use of space, also offers ideal conditions for exact load positioning.

Wire Rope Hoist

Features

- 2-speed hoisting motors (6:1)

- 2-speed travelling (4:1)

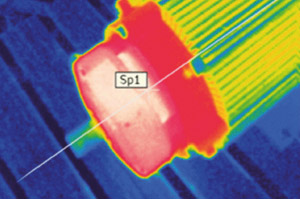

- Thermal protection for hoisting and travelling motors

- 2-step limit switch

- Electromechanical overload protection

- Operating time counter

- Cables readily placed and positioned

- Special HBC load hooks

- Two-component powder coating

- Ambient temperature -10°C up to +40°C

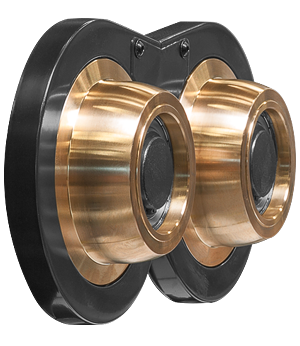

- Running wheels and fall protection made of brass

- Load hooks coated with bronze

- Radio remote control RadioMaste

- Maintenance platform

- Second hoisting gear brake NC-ND

- Drum brake NE-NF

- DIN or double load hooks

- Cable pressure roller

- Ambient temperature -20°C or +50°C

- Ambient temperature +55°C on demand

Wire Rope Hoist

Applications

Potentially explosive areas for gases and dusts

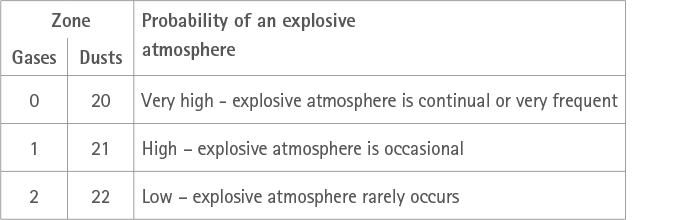

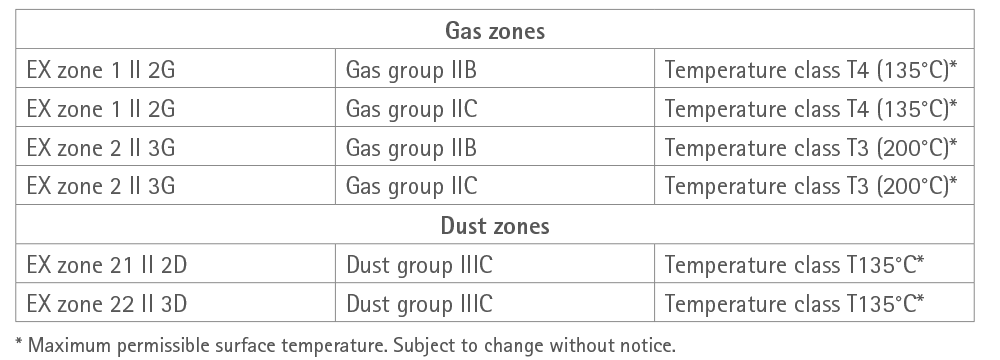

Explosion hazard areas are separated into zones. This classification, which defines the scope of protective measures to be employed, depends on the type, duration and frequency of explosive atmospheres.

The electric wire rope hoist NOVAex is approved for the following areas und zones:

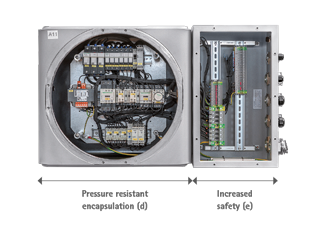

Electrical cubicles

Crane and trolley control

Electrical cubicles and cable entry points

Crane and trolley control panels in the standard DE are divided into different security areas/zones and combine „Pressure resistant encapsulation (d)“ and „Increased safety (e)“. All connections necessary have already been made at the factory by certified specialist staff and under optimum conditions.

With respect to highest possible safety and easier handling, all necessary first installation steps and cable entry points are carried out only in the area „Increased safety (e)“, and the zone „Pressure resistant encapsulation (d)“ can remain reliably closed.

All cable and conduit entry points produce a solid and tight connection and in addition offer advanced protection against mechanical influences.

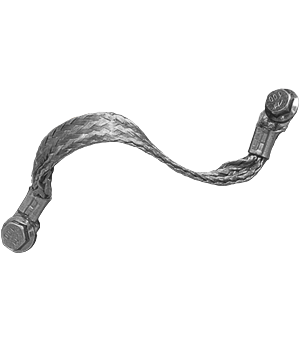

Potential equalisation

at EX crane systems

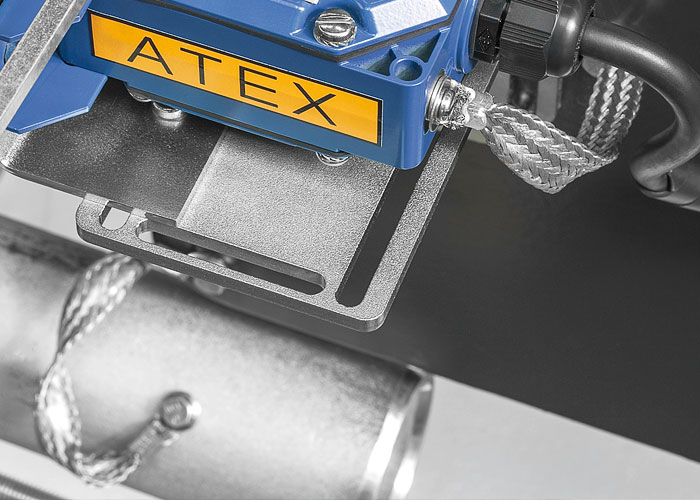

Potential equalisation using earthing strap

The installation of electrical systems in potentially explosive areas basically requires a variety of prevention measures. An indispensable protective precaution here is the potential equalisation of all live components. All components of the crane that can be live in the case of failure are connected together and then finally to the protective conductor.

In practice, not only are all electric components to be earthed without exception, but also the entire crane installation, like auxiliary structures, runways, supports, etc., is to be included in the protection measure. For reliable equalisation, for example even runway joints must thus be conductively bridged (support joints with link plates bolted over are not enough here).