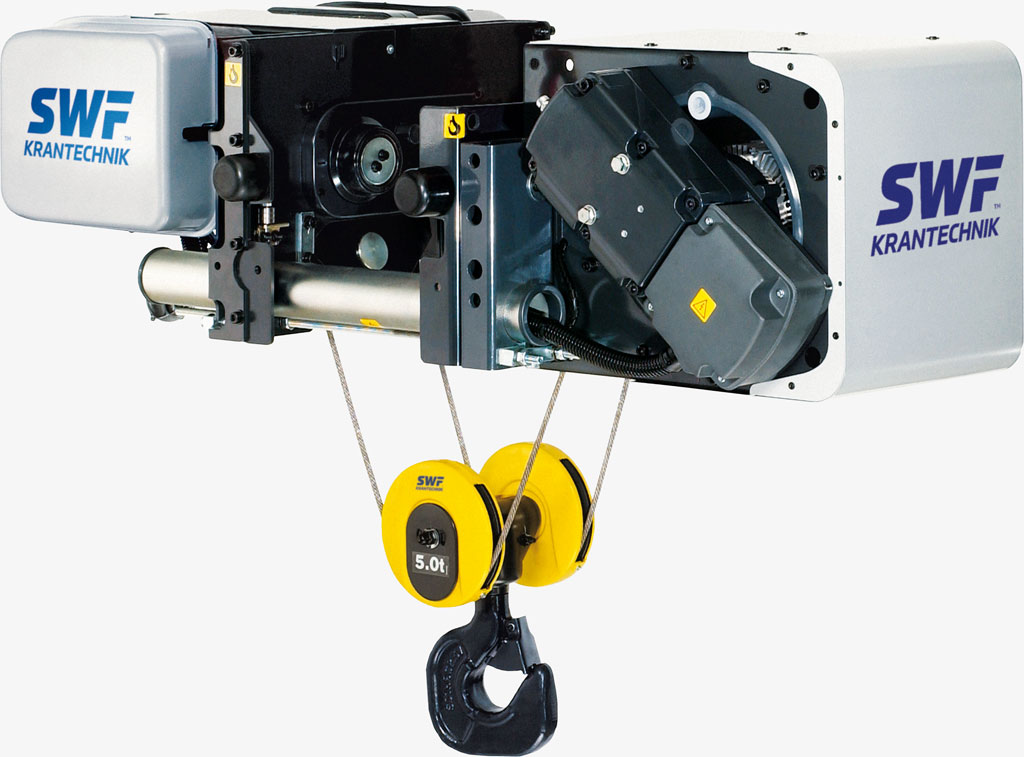

Wire Rope Hoist

NOVA1 rope

Our individually scalable and configurable NOVA wire rope hoists offer safety, effectiveness and reliability. Numerous sizes and types, coupled with an extensive range of equipment options, make customized solutions the standard and thus attractively calculable in terms of price.

The mechanical base is proven. It realizes an almost vertical lifting due to its large diameter of the rope drum, allows an optimal use of space and considerably extends the service life due to its careful handling of the mechanical parts.

Even small models can be equipped with high tech from the top class without having to jump up a class. Electronic assistance systems (Crane Intelligence features) optimize processes in every respect and offer “cranetainment” on top. They are simply fun and easy to use.

Wire Rope Hoist

FeaturesStandard equipment:- 2speed hoisting motors (6/1)

- Hoist condition monitoring system NovaMaster with Safe Working Period Counter (NOVA NE/NF)

- 4step hoisting limit switch with slowdown function and phase mismatch protection

- Electronic overload protection

- Thermal protection for hoisting and travelling motors

- Travelling machinery with frequency inverter, 2step or stepless

- Standard 3phase voltages 380/400/415 V 50 Hz; 440/460/480 V 60 Hz

- 48 V contactor control

- IP 55 protection, duty factor 60 %

- Electrical assembly and wiring in accordance with IEC standards

- Robust rope guide made of cast iron

- Epoxy paint, 60 μm

Options:- IP65 control pendant with plug adapter and EmergencyStop

- Radio remote control

- Hoist condition monitoring system NovaMaster with Safe Working Period Counter (NOVA NB/NC/ND)

- Load summation for max. 4 hoists with NovaMaster

- Hoisting inverter with ESR

- 2step trolley travel limit switch

- External fan for hoisting motor

- Standby heating for bridge panels and motors

- Special operating voltage 208 – 690 V 50/60 Hz

- IP66 protection

- Ambient temperature -20°C to +55°C

- Explosion proof version

- Stainless steel hoist panel

- Rain covers

- Articulated trolley for curved track

- Drum brake

- Lockable hook/ramshorn hook

- Cable reel

- and much more

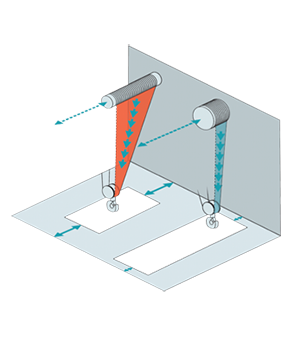

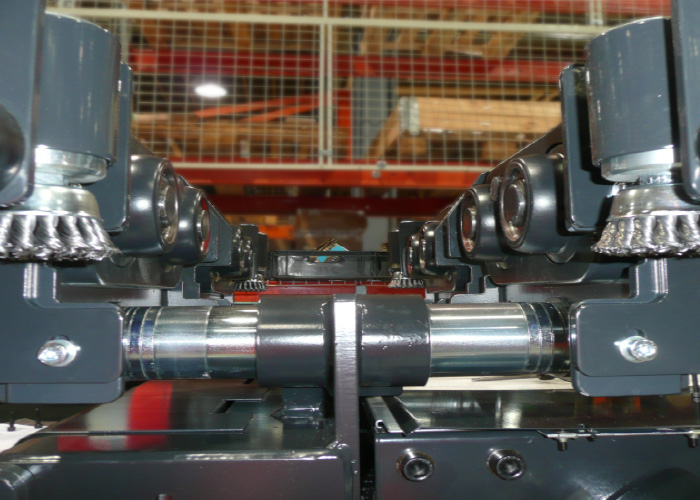

Wire rope drive

Benefits:

- Low lateral hook movement

- Improved use of space

-

Less wear on the wire rope drive

Thanks to its large drum diameter, it not only uses the space better but also optimises wear in the wire rope drive and minimises lateral hook movement. This means that loads can be reliably transported with extreme precision and placed with ultimate accuracy, thanks to the minimal diagonal pull.

Rope guide

Benefits:

- Reliable, low wear guidance of the rope on the drum

-

Simple assembly/disassembly for maintenance

The useful life of the rope is considerably enhanced by the optimised, low impact guidance. Active hoisting forces can thus be transferred uniformly from the wire rope onto the drum. The rope guides are made from metal and are robust and durable.

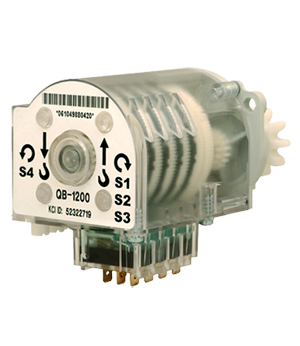

Lifting limit switch

Benefits:

- No mechanical actuation by the hook block

- Protected installation in the casing

-

No loss of build height

The lifting limit switch is well protected against external influences and is located inside the casing. Its reliability and security of function is excellent as it has no mechanical actuators or wear parts. Four fully selectable switching points ensure an automatic switchover from "fast" to "slow" in the top position, for instance.

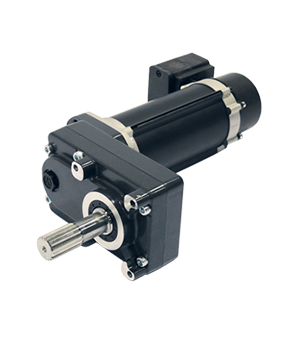

Gearbox

Benefits:

- Large bandwidth of speeds

- Quiet and vibration-free

-

Long service life

The lightweight yet compact gearbox offers a number of ratios and hence a wide range of speeds. Quiet and vibration-free running is achieved by using ground, helical gears. The gearbox is manufactured in our own, rigorously monitored production facility and is lubricated for its long service life.

Hoist motor

Benefits:

- Slow speed for precise working

- High speed for high productivity

-

Low maintenance and wear, longer motor service life

The hoist motor with its output of up to 35 kW, actually combines two motors with a power ratio of 6:1 in one cylinder and thus ensures not only safe and productive working under full load, but also ensures precise load handling at low speeds. The minimal wear and service requirement also ensures economical operation of the pole-switched motor.

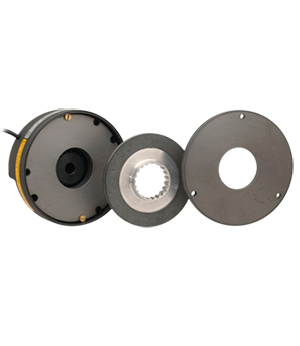

Hoist brake

Benefits:

- High degree of safety

- High braking torque disc brake

-

Designed for the service life, for one million switching cycles

The low-maintenance disc brake with its high braking torque guarantees safe operation of the hoist. It is designed for one million switching cycles and operates reliably over its long service life. It is well protected against external influences thanks to its completely closed casing.

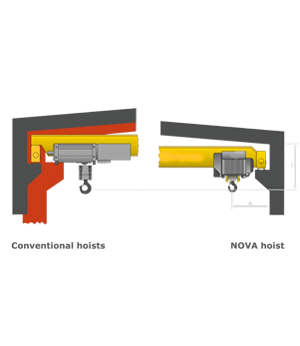

Space utilisation

Benefits:

- Optimal space utilisation

- Compact dimensions and optimum approach dimensions

-

Minimal hook dimensions

The large diameter of the rope drum and the compact arrangement of the control elements allow the best practicable approach dimensions and ideal utilisation of the space. The minimal lateral hook movement also reduces the pendulum motion of the load.

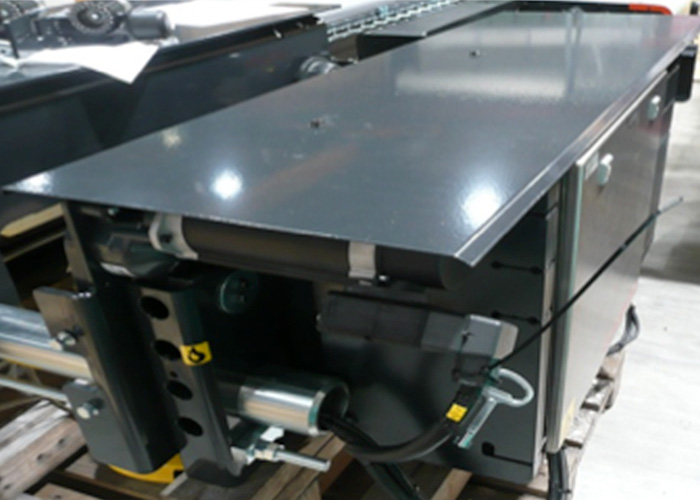

Travelling machinery

Benefits:

- Smooth and precise operation (5 to 20 m/min)

- Enhanced safety because of low sway travel

-

Adjustable frequency inverter

The electrical travelling machinery transfers its power to two wheels equally and thereby guarantees safe cross travel without the need for additional pressure rollers. The speeds can be adjusted continuously in the range from 5 to 20 m/min. This means that, in addition to sway-free travel, both smooth and precise working and fast travelling are possible. Permanently lubricated, low wear and fitted with a built-in overheat protection, a long service life is guaranteed.

Frequenzumrichter – VARIO control

Benefits:

- Smooth starting and stopping

-

Service live of many components is considerably enhanced

The frequency inverter permits precise handling of heavy loads with rapid hoisting speeds presenting low stress, and hence considerably enhances productivity. The mechanical load, and the associated wear on many components is reduced by the smooth start and stop and the prevention of impact loads. In addition, energy consumption is lowered thanks to the optimal power regulation.

Crane Intelligence

Benefits:

- Safer, more effective and at the same time cost-optimized load handling

-

Perfected monitoring and control processes

-

Greater flexibility, the crane can be used in more work processes

The electronic monitoring and control features (Crane Intelligence) perfect the control and monitoring processes of experienced crane operators using a "second brain". The performance of the entire crane can thus be fully utilized at all times, while protecting the load and the technology.

Wire Rope Hoist

TypesNOVA L

- Single girder trolley

- low headroom

- up to 12.5 t

NOVA M

- Double girder trolley

- up to 80 t

NOVA N

- Single girder trolley

- normal headroom

- up to 40 t

NOVA F

- Fixed hoist for free-standing installations

- up to 80 t

NOVA

- Machinery hoist

- for machinery and plant engineering

- up to 10 t

A-motor & S-motor

Frequency inverterThe optionally available A-motor can save up to half the energy costs compared with the conventional two-stage motor with contactor control and thus demonstrates not just economical but also ecological advantages.

Furthermore, productivity can be significantly improved by quicker handling of small loads and precise handling of heavy items.

The sample calculation below for a 10 t hoist operating for 10 years, 240 days per year, at an average of around one hour a day demonstrates the advantages mentioned:A-Motor P-Motor hoist speed m/min 0.25 ... 2.5(7.5) 0.8/5 motor output kW 4.5 9.0 over the full service life kWh 10,800 21,600 costs €/kWh ≈0.10 ≈0.10 energy costs € ≈1,000 ≈2,000 for the entire service

Wire Rope Hoist

Options-

Rain protection cover

Rain protection covers give our rope hoists a good look, even in bad or hot weather. The powder-coated covers are solid and offer the motors and electrical systems protection against rain, dust (from above) and direct sunlight.

-

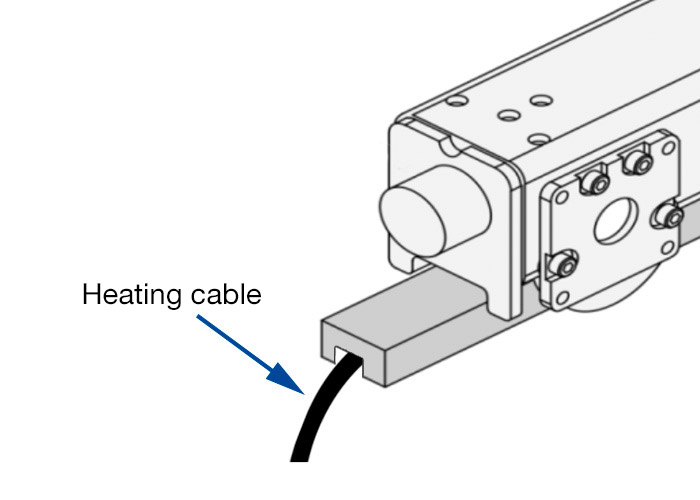

Cross rail heating

Reliable operation is always ensured, even at below-zero temperatures, thanks to the cross rail heating. Thermostatically controlled heating guarantees an ice-free rail for double-girder cranes, even over a length of 45 m and at -20°C ambient temperature (50 m -> -10 °C). The heating cable for this system is laid directly in a cavity in the rail, unlike on single-girder cranes, where it is in a pipe welded to the hook block.

-

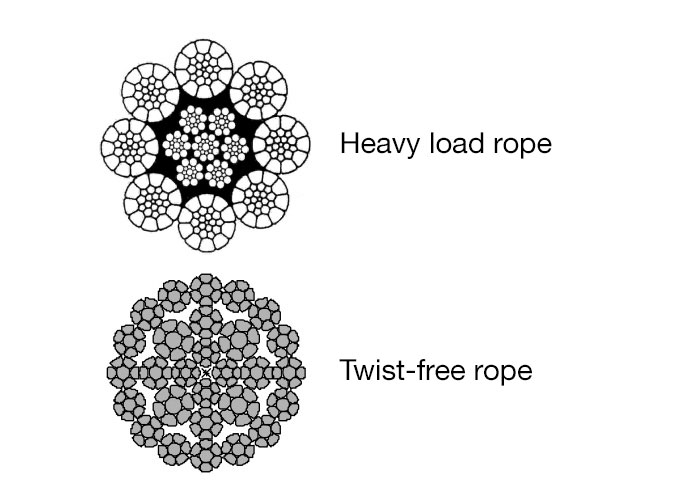

Special ropes

Various different ropes may be used to provide individual adaptation and adjustment of the hoist: the heavy load ropes have a high number of possible lifting cycles and are particularly suited for grab operation, tambour handling, in the steel industry or on automatic cranes. The twist-free ropes allow very high hoisting heights and are the best option for single wire applications (e.g. winches in plant engineering). Stainless steel ropes are also possible. The latter have benefits despite their halved loadbearing capacity.

-

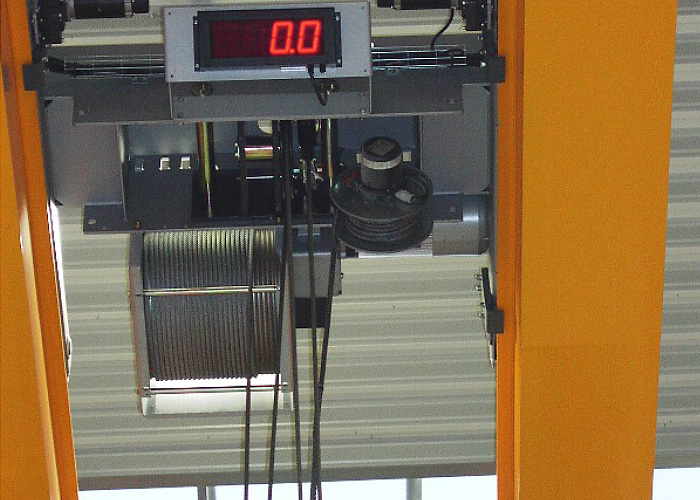

Cable drum

The cable drum can provide a reliable power supply for motorised hooks, grabs, magnets or other special functions up to a height of 26 m.

Standard solutions:

• Three-phase power supply 4x 2.5 mm² 16 A • Motorised hook/grab/magnet 7x 2.5 mm² 16 A • Grab/magnet with rotation function 12x 2.5 mm² 16 A • Special function with up to 18x 2.5 mm² 16 A • Special applications on request

-

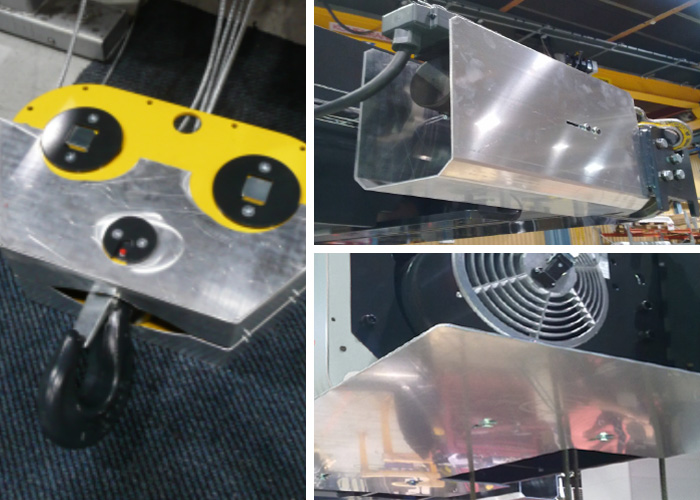

Motorised hook

The motorised rotatable hooks improve load handling and allow a broad application range. Productivity is optimised by the improved load control which simultaneously enhances safety. All the necessary components such as the hook block, special reeving, cable drum and the electrical components required are supplied. A large rope-to-rope base prevents twisting of the hook block.

-

Protective plates against radiant heat

In locations with extreme conditions and high radiant heat, the additional aluminium protective plates can hold their "hand" in front of the motors, the electrical system or the hook and significantly dampen the influence of heat.

-

Rail brushes

It is not always possible to guarantee clean rails and therefore the safe, reliable and stable crane travel associated with this. The rotating rail brushes are the appropriate accessory for this situation and ensure that the running surface is always clean. The rail brushes are available for various carriages and also underslung end carriages.

-

Crane lighting

The supplementary crane lighting makes it possible to shift and position loads accurately, even in a dark environment. The lightly diffuse LED light dazzles significantly less than standard floodlights and, what's more, cuts electricity consumption by 2/3. Its long service life (up to 50,000 hours) and immediate availability without a long start-up phase, make LED crane lighting not only economical, but also increases safety in load handling from the outset.