Electric Chain Hoist

CHAINster

We are truly proud of the new CHAINster. It tackles loads with enthusiasm, is always available when you need it and will work for a lifetime. It can cope with extreme loads and can be used for almost everything.

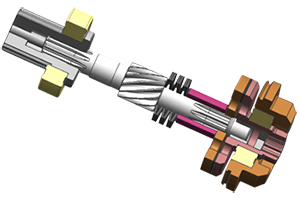

Its newly developed chain sprocket does not just give it a longer life, but is also particularly low on maintenance. The slipping clutch ensures that nothing goes wrong, even in an emergency, and its brake is designed for its service life. It is simultaneously both fast and sensitive because of its 6:1 ratio.

Electric Chain Hoist

Features

- Upper hook, push trolley or inverter controlled motor trolley

- 2 lifting speeds up to 6/1 ratio depending to load

- Up to 10,000 kg; up to 2,500 kg on a single fall

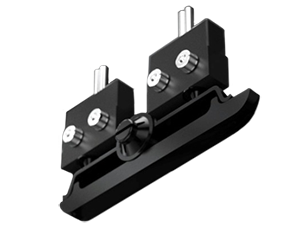

- Patented chain sprocket with intermediate teeth and metal chain guide

- Mechanical overload device

- 2-step upper and lower emergency lifting limit switch

- High-quality reliable contactor control 48 V with main switch

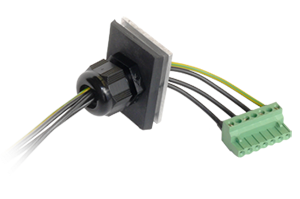

- Electrical connections plugable, for relieved maintenance

- Thermal protection for lifting motor

- Control pendant IP65 with emergency button, with plug

- Lifetime brake

- Separate brake rectifier

- Electrical provision for motor trolley

- Housing made completely from aluminum or cast

- Protection IP55

- Ambient temperature -20 °C up to +50 °C

- Epoxy powder painting, 70 µm

- Trolley limit switch

- Upper eye suspension instead of hook

- Load chain made from stainless steel

- 2 step and 4 step gear limit switch

- Second hoisting brake

- Manual brake release

- Rain cover

- Remote radio control „RadioMaster“

- Explosion-proof application

- Special power supply 230V up to 675V, 3 phases

- HandyMaster for increased efficiency

- Version for food industry

Electric Chain Hoist

Types

Die Hubwerkseinstufung (FEM/ISO) ist eine Kennzahl die sich primär aus der mittleren täglichen Laufzeit des Krans und der tatsächlichen Last zusammensetzt. Hierbei wird auch berücksichtigt wie oft das Hebezeuge hierbei Höchstbeanspruchungen oder nur geringen Beanspruchungen ausgesetzt ist oder wie viele Starts/Stops erfolgen.

Vereinfacht:

1Am / M4 = Die mittlere tägliche Laufzeit beträgt rund 1 Stunde und das Hebezeug wird häufig höchstbeansprucht und laufend mittleren Beanspruchungen ausgesetzt.

2m / M5 = Die mittlere tägliche Laufzeit beträgt rund 2 Stunden und das Hebezeug wird häufig höchstbeansprucht und laufend mittleren Beanspruchungen ausgesetzt.