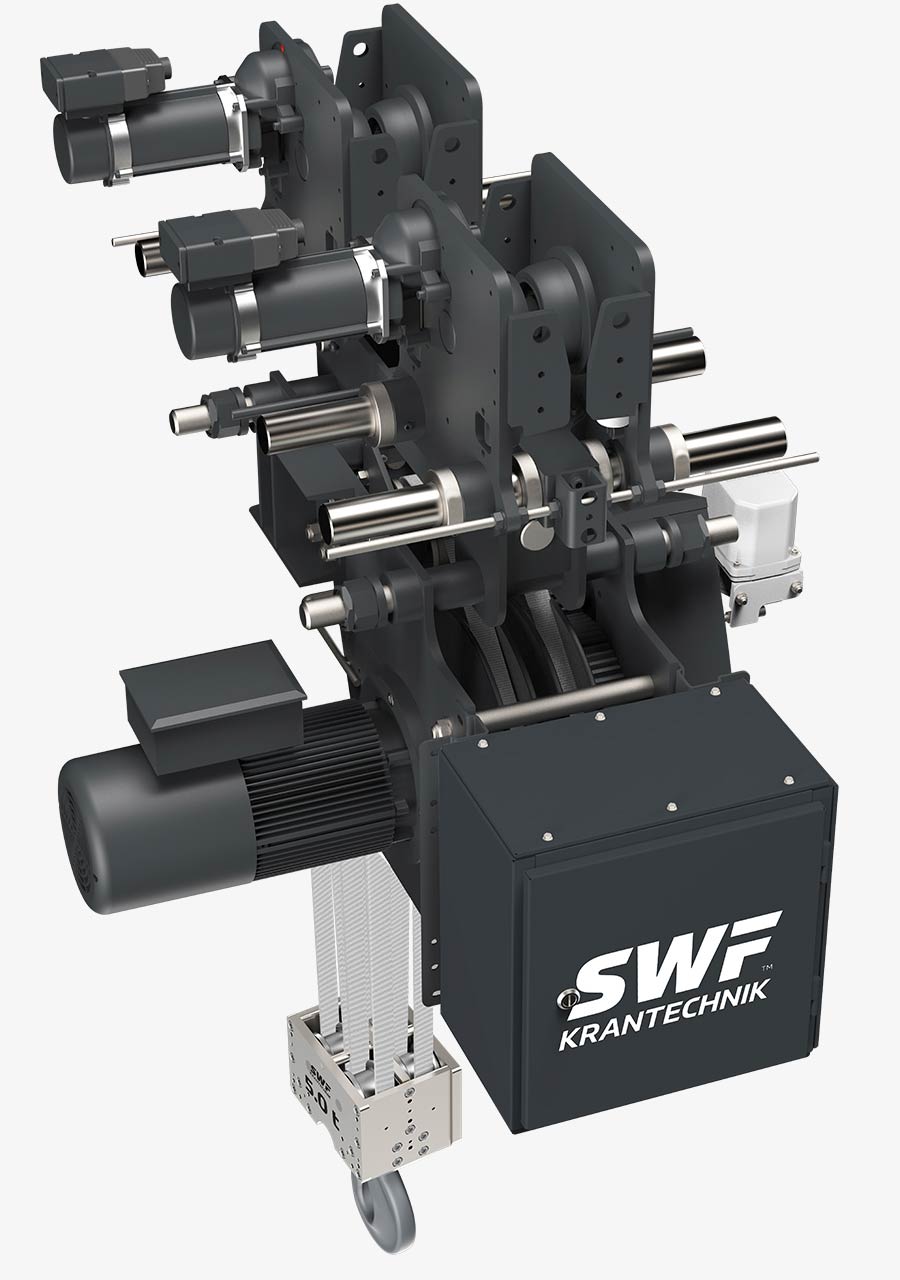

Electric belt hoist

ATHLO belt

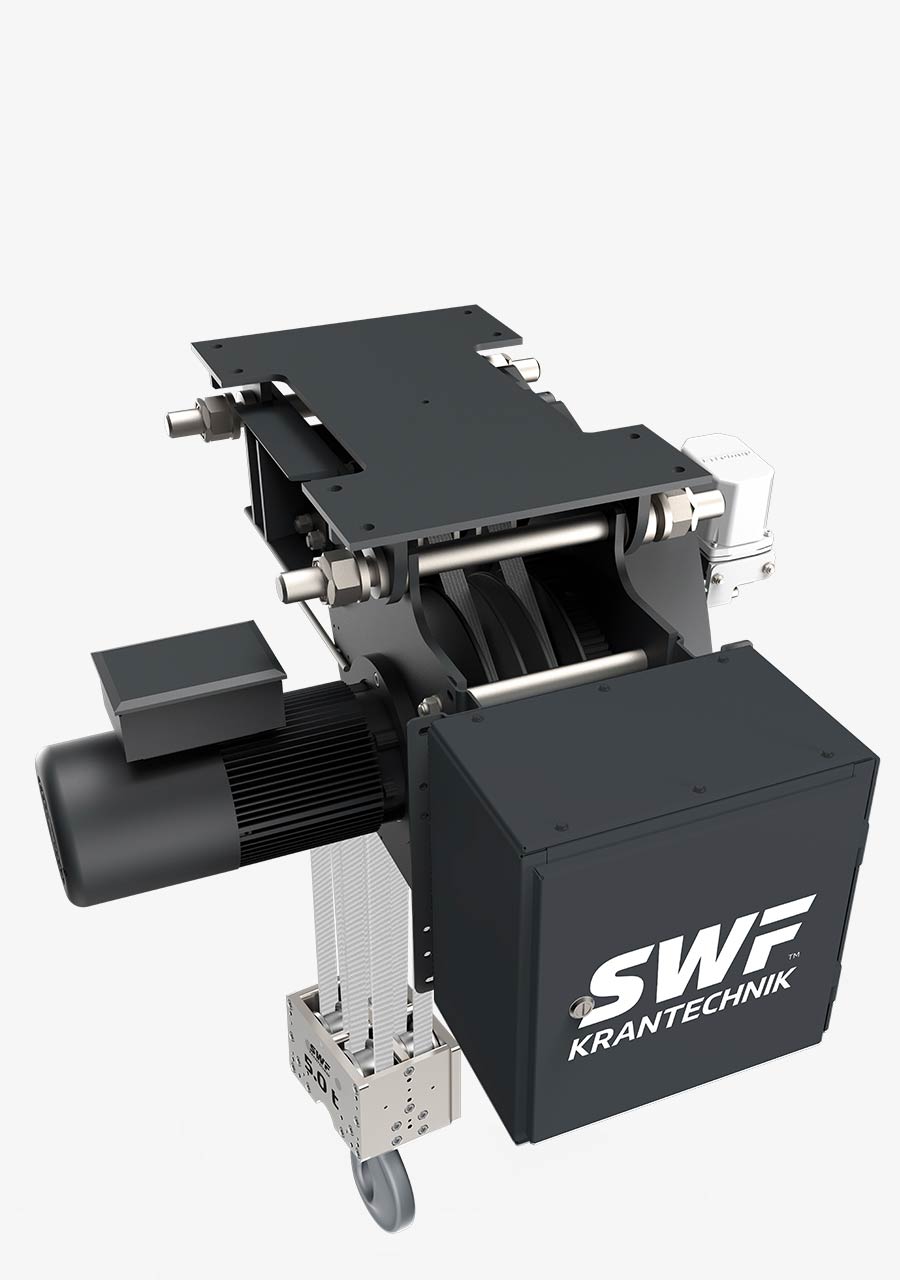

Our belt hoist ATHLO belt presents its advantages wherever cleanliness and safety are important. It covers a wide load range from 500 to currently 5,000 kg. Other models with loads up to 10,000 kg will follow over time.

The numerous series features enable reliable and always safe operation. ATHLO belt can also be optimally adapted to individual requirements. In addition to the already available models with stainless steel components, further components in stainless steel will follow.

ATHLO belt is designed for the food sector, the chemical/pharmaceutical industry and for all comparable industries.

Electric belt hoist

FeaturesStandard- For loads from 500 kg – 5,000 kg (further loads will follow)

- 2 mechanical hoisting speeds (ratio 1/6)

- Lifting height: 4,5 – 9 m (depending on the hoist)

- Standard operating voltage: 380 V – 415 V; 50 Hz

- Stepless traveling machinery 5-20 m/min

- Overload protection

- Protection class of the hoisting motor: IP 55; insulation class: F

- Overheat protection

- Upper and lower adjustable limit switches

- Contactor control (48 V)

- Control with proven strain relief

- Electrically isolated hook block

Options (Availability depending on size)- Corrosion protection version with stainless steel components

- Version with fixed suspension or push or trolley

- Stainless steel hook and hook block

- BH2 compatible with ProfileMaster plus light crane system

- Stainless steel heat shield

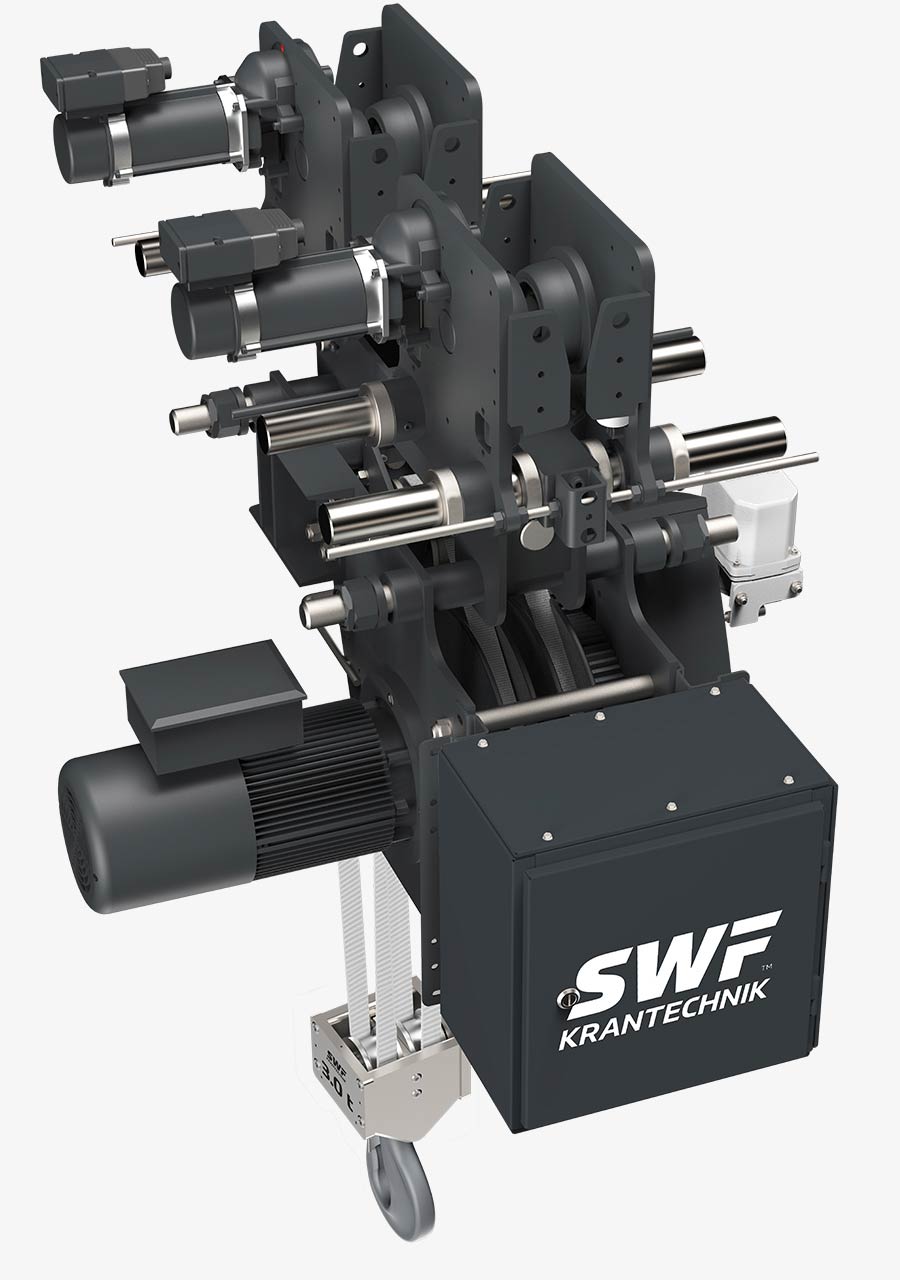

Hoisting motor + brake

Benefits:

- Powerful hoisting motor

- Protection class of the hoisting motor: IP 55; insulation class: F

- Overheat protection

-

Size 2 offers self-adjusting hoisting brake with wear control

The proven hoisting motor is contactor-controlled and enables two lifting speeds (1/6; optional lifting and lowering controlled by frequency inverter). For maximum safety, an overheat protection is standard (Klixon).

Contactor control/Limit switch

Benefits:

- Proven contactor control (48V)

- Frequency inverter for stepless lifting and lowering (optional)

- Comfortable 2-step hoisting limit switch

- Protected installation in the casing

-

Upper and lower limits are easily adjustable

As standard, ATHLO belt is equipped with a robust and proven contactor control (2 hoisting speeds, 1/6).

The frequency inverter enables stepless and exact lifting speeds. Very slow lifting and lowering ensures maximum precision and safety.

Hoisting gear

Benefits:

- Powerful, durable hoisting gear

-

Various gear lubricants configurable (standard or food grade)

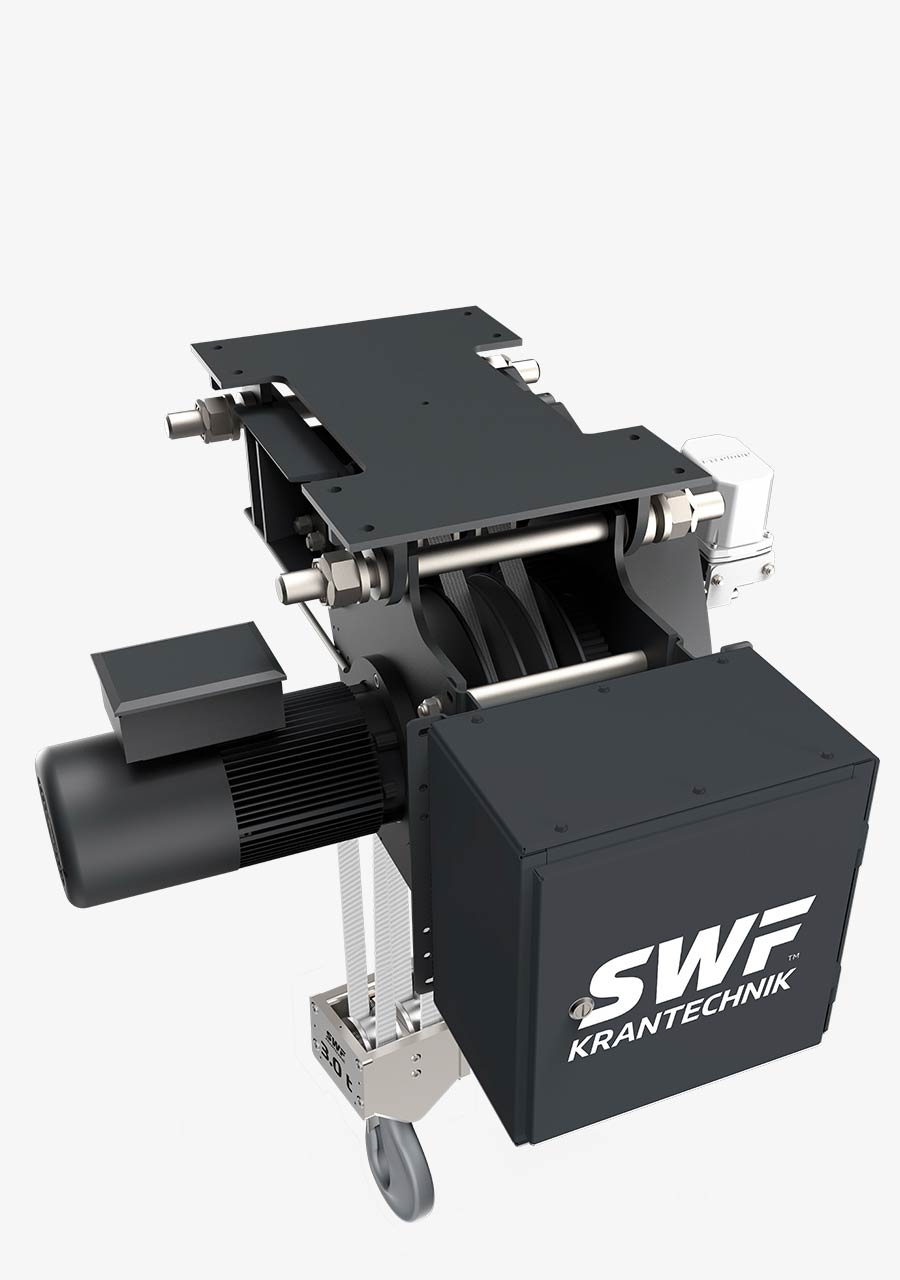

Construction

Benefits:

- Small C hoist dimension = optimal use of space

-

Robust construction (steel; optional with stainless steel components)

All components of the ATHLO belt are arranged in such a way that a good use of space is guaranteed. The belt hoist is also available with stainless steel components.

Depending on the requirements, ATHLO belt can be equipped with a fixed suspension or a push or motor trolley or swivelling trolley.

Electric belt hoist

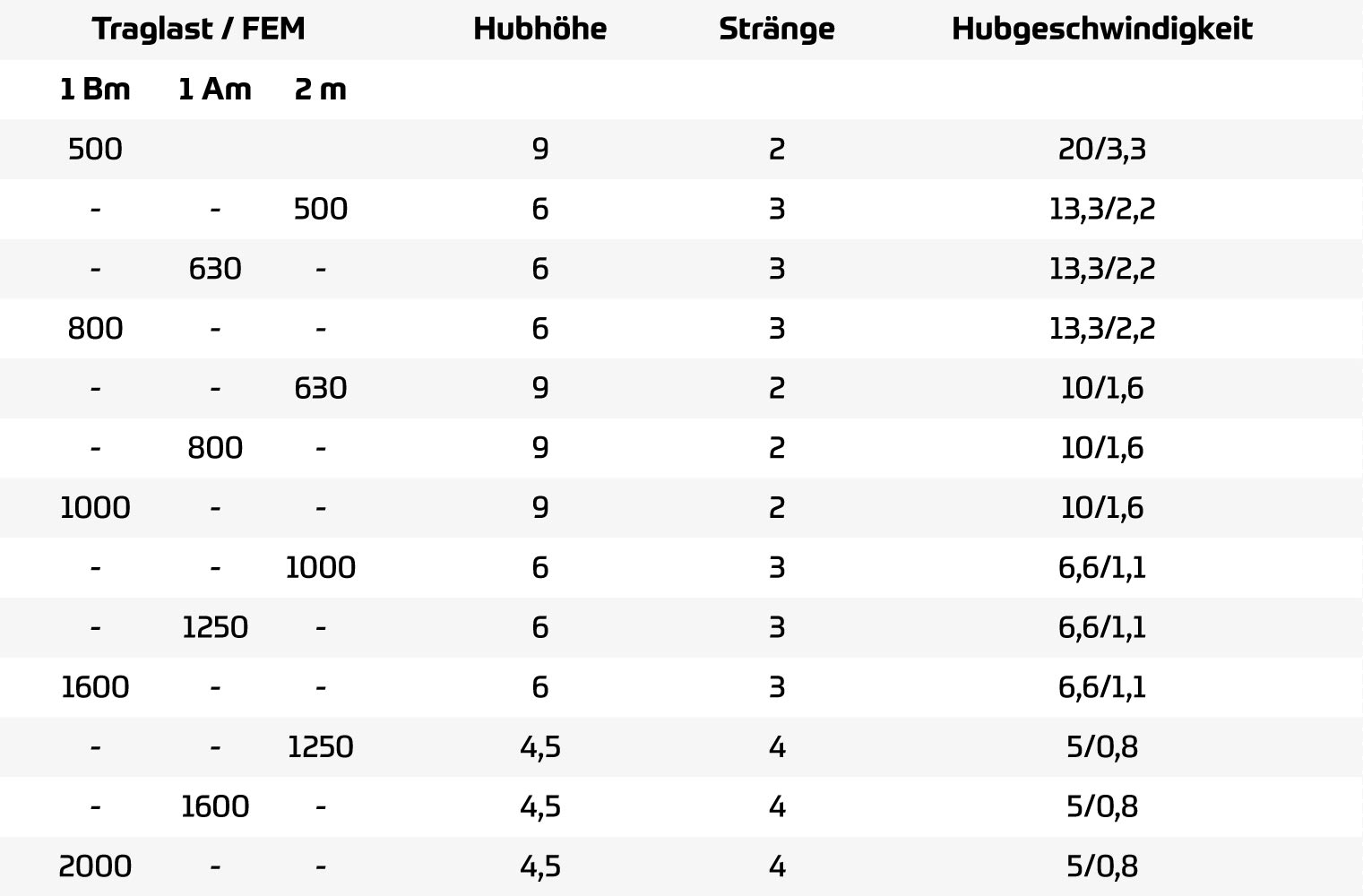

Types

ATHLO belt (double fall, Size 2)

Load (FEM; Lifting speed):

500 kg (1Bm; 20/3.3 m/min)

630 kg (2m; 10/1.6 m/min)

800 kg (1Am; 10/1.6 m/min)

1000 kg (1Bm; 10/1.6 m/min)

Lifting height:

up to 9 m

ATHLO belt (three fall, Size 2)

Load (FEM; Lifting speed):

500 kg (2m; 13.3/2.2 m/min)

630 kg (1Am; 13.3/2.2 m/min)

800 kg (1Bm; 13.3/2.2 m/min)

1000 kg (2m; 6.6/1.1 m/min)

1250 kg (1Am; 6.6/1.1 m/min)

1600 kg (1Bm; 6.6/1.1 m/min)

Lifting height:

up to 6 m

ATHLO belt (four fall, Size 2)

Load (FEM; Lifting speed):

1250 kg (2m; 5/0.8 m/min)

1600 kg (1Am; 5/0.8 m/min)

2000 kg (1Bm; 5/0.8 m/min)

Lifting height:

up to 4.5 m

ATHLO belt (2x2, Size 5)

Load (FEM; Lifting speed):

2500 kg (1Am; 5.9/0.9 m/mi)

3200 kg (1Bm; 5.9/0.9 m/min)

Lifting height:

up to 8.2 m

ATHLO belt (2x4, Size 5)

Load (FEM; Lifting speed):

4000 kg (2m; 3.8/0.6 m/min)

5000 kg (1Am; 3.6/0.6 m/min)

Lifting height:

up to 5.9 m

Info zu FEM/ISO:Die Hubwerkseinstufung (FEM/ISO) ist eine Kennzahl die sich primär aus der mittleren täglichen Laufzeit des Krans und der tatsächlichen Last zusammensetzt. Hierbei wird auch berücksichtigt wie oft das Hebezeuge hierbei Höchstbeanspruchungen oder nur geringen Beanspruchungen ausgesetzt ist oder wie viele Starts/Stops erfolgen.

Vereinfacht:

1Am / M4 = Die mittlere tägliche Laufzeit beträgt rund 1 Stunde und das Hebezeug wird häufig höchstbeansprucht und laufend mittleren Beanspruchungen ausgesetzt.

2m / M5 = Die mittlere tägliche Laufzeit beträgt rund 2 Stunden und das Hebezeug wird häufig höchstbeansprucht und laufend mittleren Beanspruchungen ausgesetzt.