Electric Chain Hoist

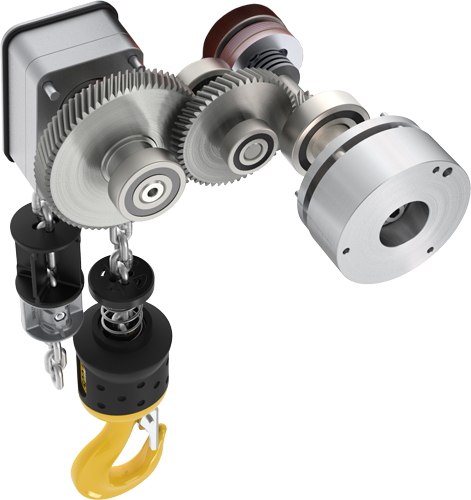

ATHLO chain EX Zone 22

The ATHLO chain EX Zone 22 series combines the advantages of our proven chain hoist with the operational capability for potentially explosive atmospheres. The new generation of explosion-proof electric chain hoists is designed for loads from 160 to 1,000 kg (further loads will follow).

The chain hoists comply with the applicable national and international norms and safety standards (ATEX, IECEx, NEC) and can be used flexibly. The aspects of safety, product service life, ease of maintenance, performance and easy usage were the focus of the development.

Electric Chain Hoist

Features

- Thermal protection for hoist motor

- Thermal protection for gear

- Brake and slipping clutch

- Limit switch for safe lifting and lowering

- Hook block with two bearings

- Foldable upper suspension hook (optimal C hoist dimension)

- Flat cable and round cable gland

- Pressure rollers / counterweights for trolley

- Limit switch (deceleration/stop)

- Towing arm

- Rain cover

- Self-locking hook

- Stainless steel hook block

- Stainless steel chain

- Food safety lubricant

- Manual brake release

- Key switch on emergency stop button

- Adapter to C-trolley

- Fixed suspension (up to 1250 kg)

- Time meter

- Hardwired control

Electric Chain Hoist

Types

Die Hubwerkseinstufung (FEM/ISO) ist eine Kennzahl die sich primär aus der mittleren täglichen Laufzeit des Krans und der tatsächlichen Last zusammensetzt. Hierbei wird auch berücksichtigt wie oft das Hebezeuge hierbei Höchstbeanspruchungen oder nur geringen Beanspruchungen ausgesetzt ist oder wie viele Starts/Stops erfolgen.

Vereinfacht:

1Am / M4 = Die mittlere tägliche Laufzeit beträgt rund 1 Stunde und das Hebezeug wird häufig höchstbeansprucht und laufend mittleren Beanspruchungen ausgesetzt.

2m / M5 = Die mittlere tägliche Laufzeit beträgt rund 2 Stunden und das Hebezeug wird häufig höchstbeansprucht und laufend mittleren Beanspruchungen ausgesetzt.

Electric Chain Hoist

Applications

Potentially explosive areas for gases and dusts

Potentially explosive atmospheres are divided into zones. This classification, which ultimately determines the extent and the protective measures to be taken, depends on the type, duration and frequency of occurrence of explosive atmospheres.

For example, the environment of Zone 22 may be production or storage areas where powders or dusts are temporarily present:

flour, sugar, wood, plastic, metal, or any other substance that can form explosive clouds of dust when mixed with air.

| Zone | Probability of an explosive atmosphere | |

| Gases | Dusts | |

| 0 | 20 | Very high - explosive atmosphere present continuously or very frequently |

| 1 | 21 | High - explosive atmosphere occasionally present |

| 2 | 22 | Low - explosive atmosphere rarely present |