Hoist monitoring

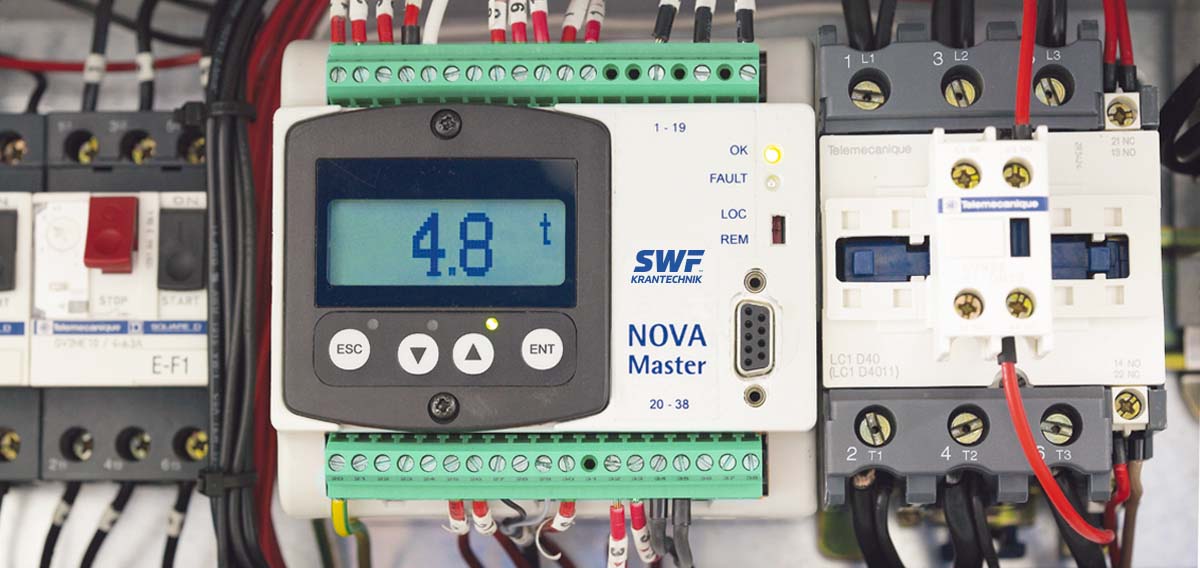

NovaMaster

NovaMaster collects and processes many hoist parameters, which are read out on a display.

In other words, the days of worrying about inaccurate or time-consuming calculations for the annual inspection of your crane systems are history.

- Remaining safe working period (SWP) of the hoist

- Total number of starts

- Total working period of the hoist motor

- Total number of hoist cycles

- Average load

- Remaining safe working period of the brake

- Load on the hook

- Supply voltage

- Overload incidents

- Emergency stop incidents

- Maximum value of the calculated duty cycle (ED)

- Total switch-on time of the crane

- Maximum measured value of the load

- …

- Relay outputs for other electrically controlled additional functions

- Intermediate loads can be programmed for the hoist

- Analogue output, for example for a large load display (0-10 V)

- RadioMaster remote control with a display indicating the current load

- Slack rope function with a bypass, e.g. for using load suspension devices

- CANbus function to network up to 5 hoists

- Multifunctional inlets e.g. for overload switching points or start/runtime counters

- Load measurements/summation optional via strain gauge sensor or motor current measurements

Hoist monitoring

Benefits

- Continuous monitoring

Hoist monitoring, permanent SWP calculations, overload protection - Minimal downtime

Relevant crane data can be read quickly from the display - Safe working conditions

Monitoring of safetyrelevant hoist components and operation parameters such as brakes, contactors, etc - Mobile hoist monitoring

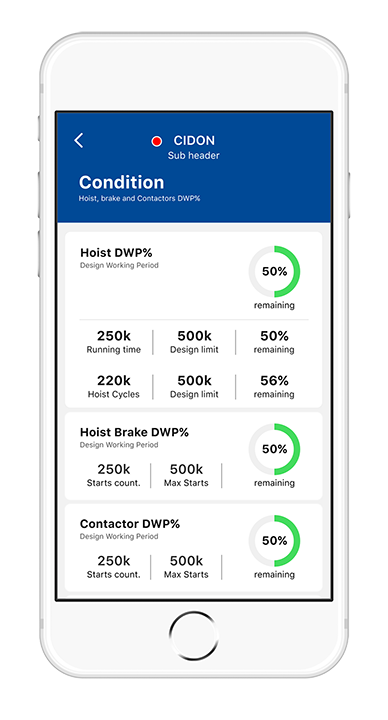

SWF X-Link clearly visualizes your hoist monitoring data conveniently on your mobile phone

SWF X-Link

NovaMaster app extension

The SWF X-Link app extends the NovaMaster hoist monitoring. The app clearly visualizes all NovaMaster parameters on the users mobile phone on factory floor level. Furthermore, all NovaMaster parameters can be exported in various formats and sent by email. This tremendously facilitates the cooperation with the service technicians onsite prior to regular maintenance inspections. The app is available for download at the AppStore or the Google Play Store. With this first version of the app we enter the remote technology area. Extensions of the app are planned.

NovaMaster simply needs to be equipped with a hardware module with antenna for wireless transmission and an adapter cable. The user then simply uses his mobile phone on the factory floor level by connecting to NovaMaster via wireless communication technology.

Reading out and evaluating the parameters with SWF X-Link before the regular maintenance inspections supports the service technicians prior to onsite services. On the day of the hoist service, the NovaMaster data is simply read out, archived and can be any time compared with data from previous onsite services.